Below you can see a series of projects we have lead and developed. We offer technical support and consultancy from ideation/design to realization

Custom design of an electric mountain bike with frame made from aluminum processing.

Design of a “pack” to turn a standard bike into a three-wheeled bike with double front wheel. The goal is to make the bike usable by those with balance-related problems such as neuronal diseases.

Dalcor Engineering supported Boscoscuro in the creation of the geometry of the new frame of its motorbike with which it participates in the Moto2 world championship. A new chassis designed to obtain structural and dynamic performance according to the manufacturer’s instructions.

Design and sizing of a maintenance pylon for the new Paris metro station. It is a 22m pylon positioned on a circular structure. The truss runs along the entire circumference while radial positioning is achieved thanks to a mobile platform that moves on the pylon itself. Dalcor Engineering supported the customer in the design, sizing and documentation relating to the structure and movement of the entire system.

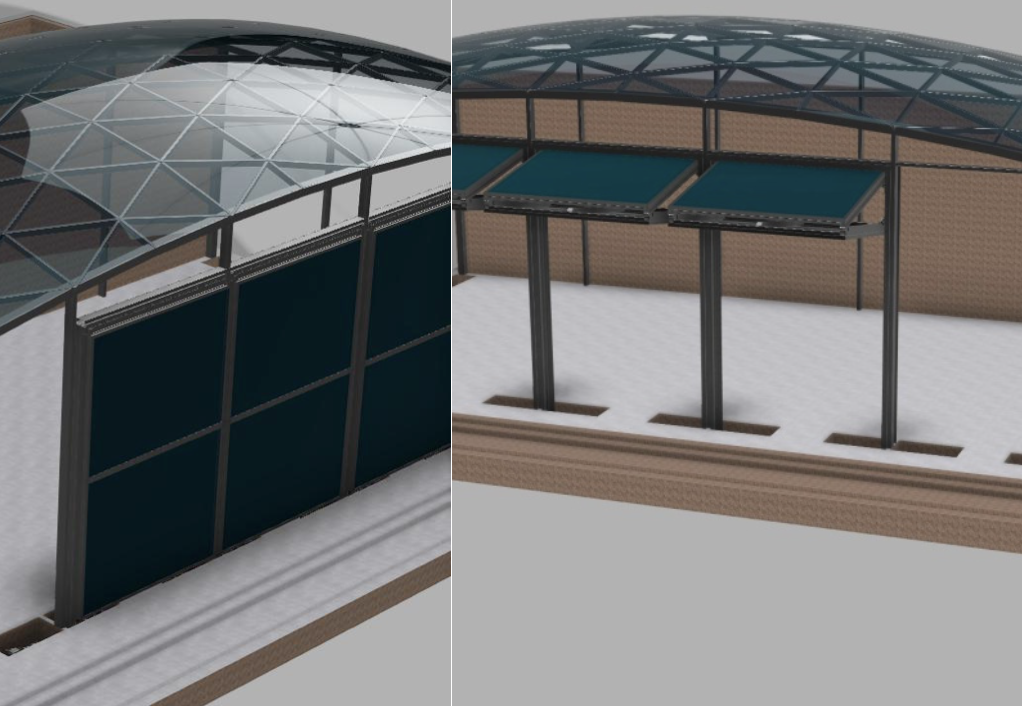

Design and sizing of a retractable glass roof with a span of 17m, composed of 3 modules that open and close the roof according to the customer’s needs.

Design and sizing of a mechanism for lifting 11 glass doors weighing 6 tons in 2 layers, doors intended for a private home (see also the videos).

Design and sizing of the movement mechanism of an architectural wall for the setting up of a SPA area on the Norwegian Prima cruise ship (see also the videos).

Design and sizing of the movement mechanism of a pedicure chair, vertical and horizontal movement with automatic adjustment.

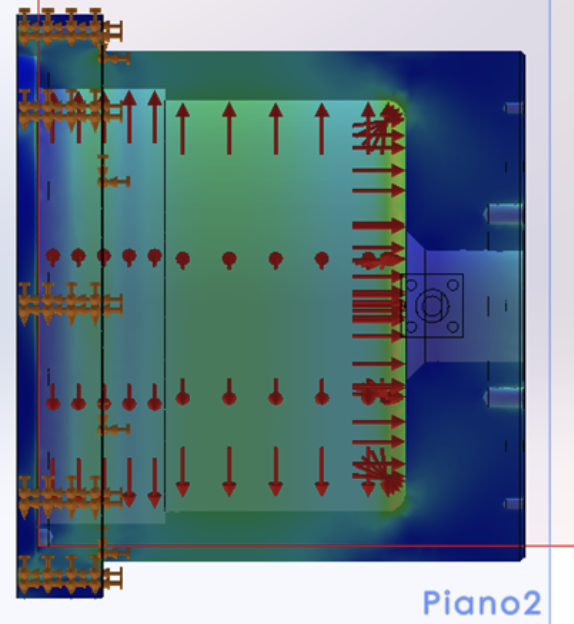

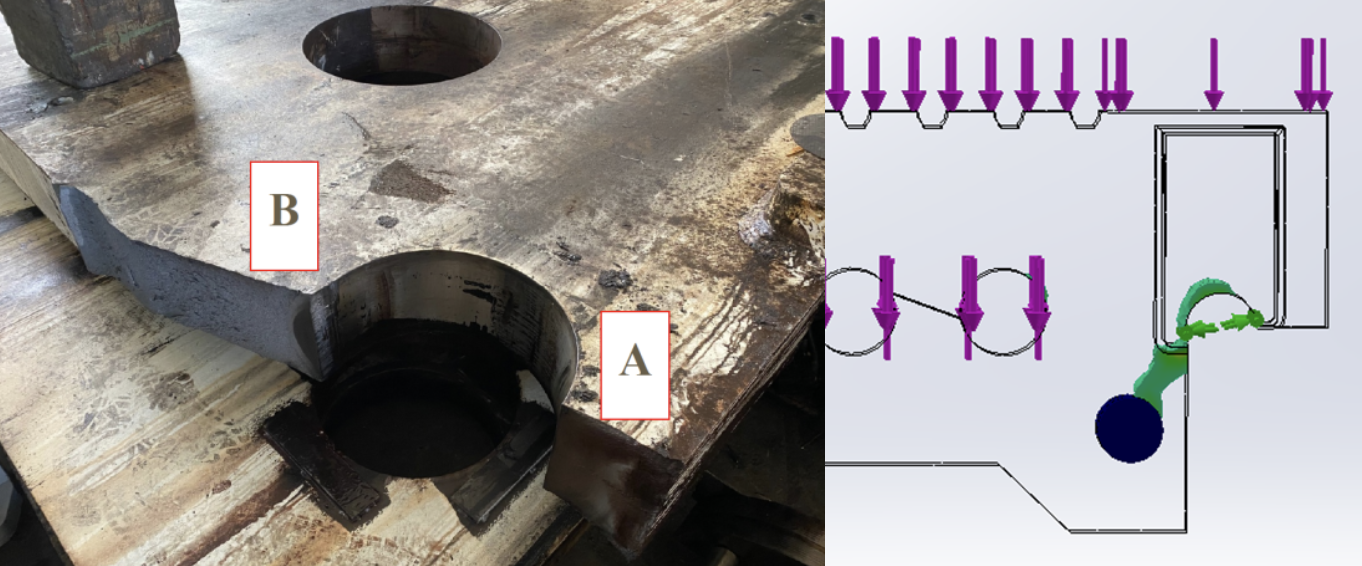

For certain steels, heat treatment leads to structural collapse of the same, which is why the customer consulted Dalcor Engineering to optimize the geometry of the supports, trying to identify the best solution to avoid tension peaks at the support.

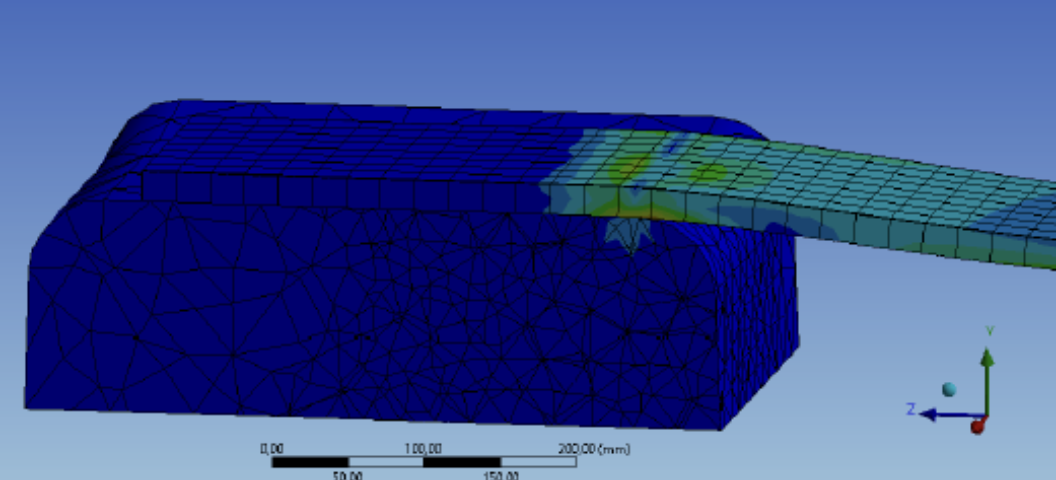

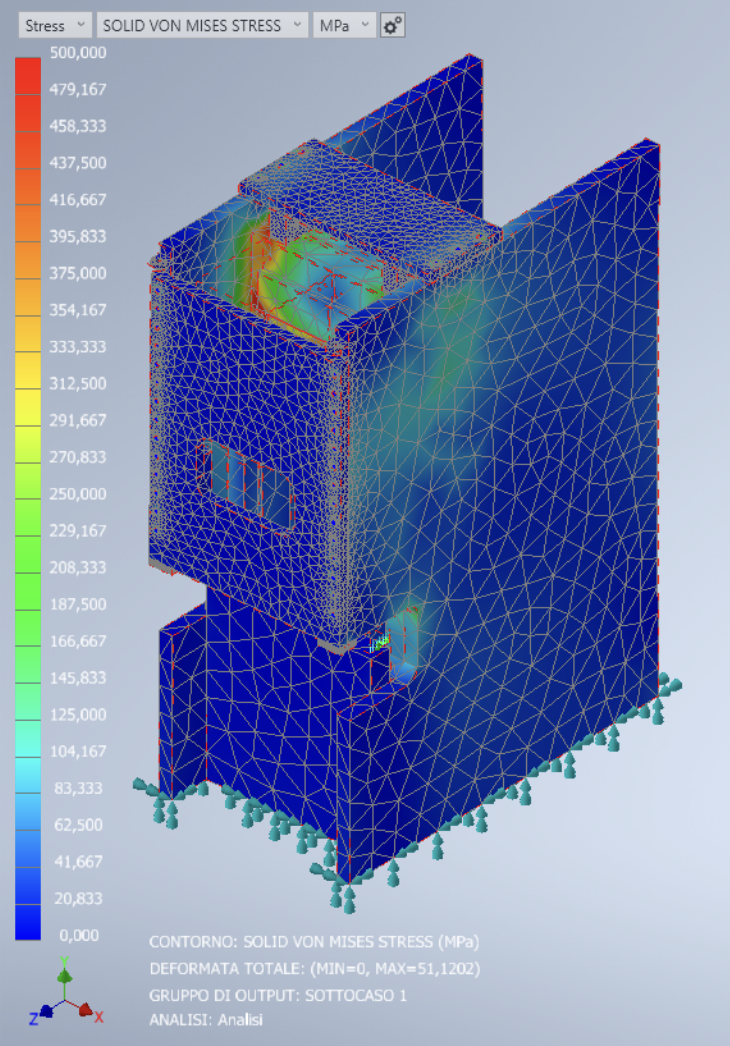

Following a crack on the top of a calibration press, an analysis of the localized stresses was carried out, identifying the best geometry to avoid the concentration of stress where the crack had previously been identified.

An analysis of the stresses was carried out on a press used for bending the longitudinal edges of the sheets intended for the production of pipes in order to validate and size the structural reinforcement interventions.

An analysis of the stresses on the bench of a bending machine following its failure was carried out.

In this case Dalcor Engineering provided the customer with a complete report related to the breakage, which highlighted the presence of a defect that caused the crack to propagate.

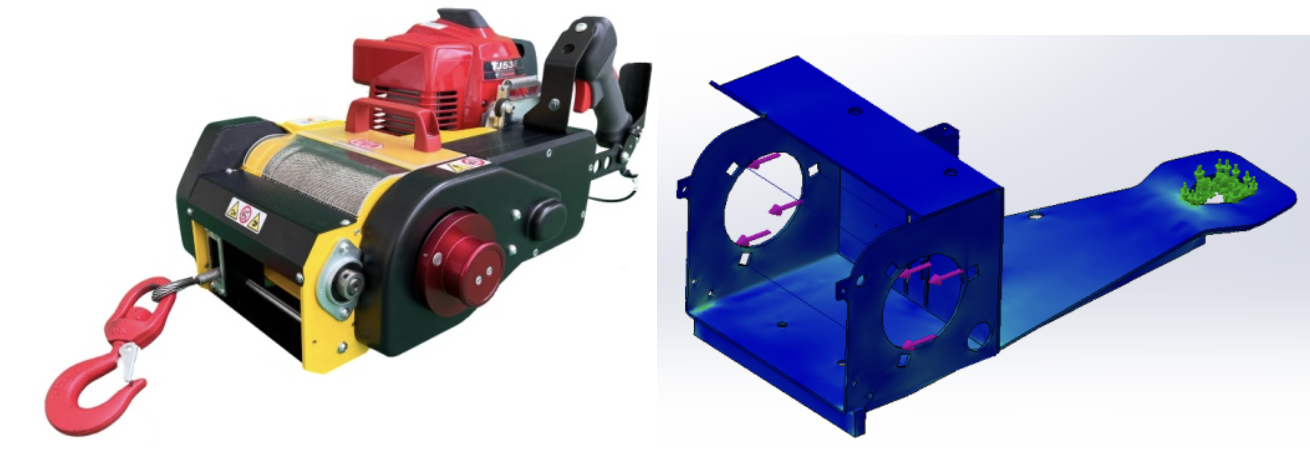

Dalcor Engineering supports the customer DVA S.r.l. in the analysis and optimization of the range of products currently on the market. The objective is to innovate the products, guaranteeing maximum safety for the operator and making the product usable with maximum convenience for the customer.