Continuous chrome plating systems

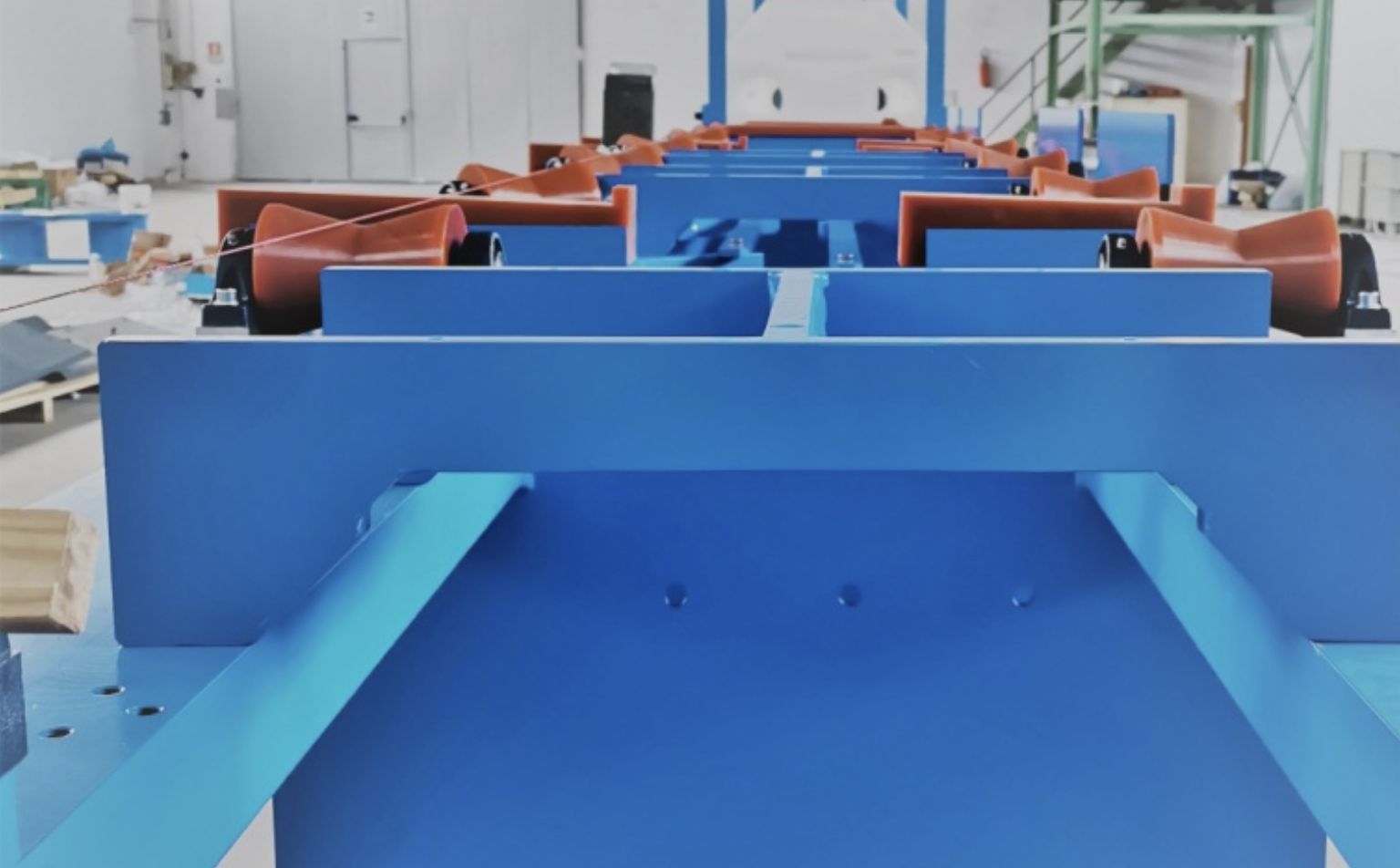

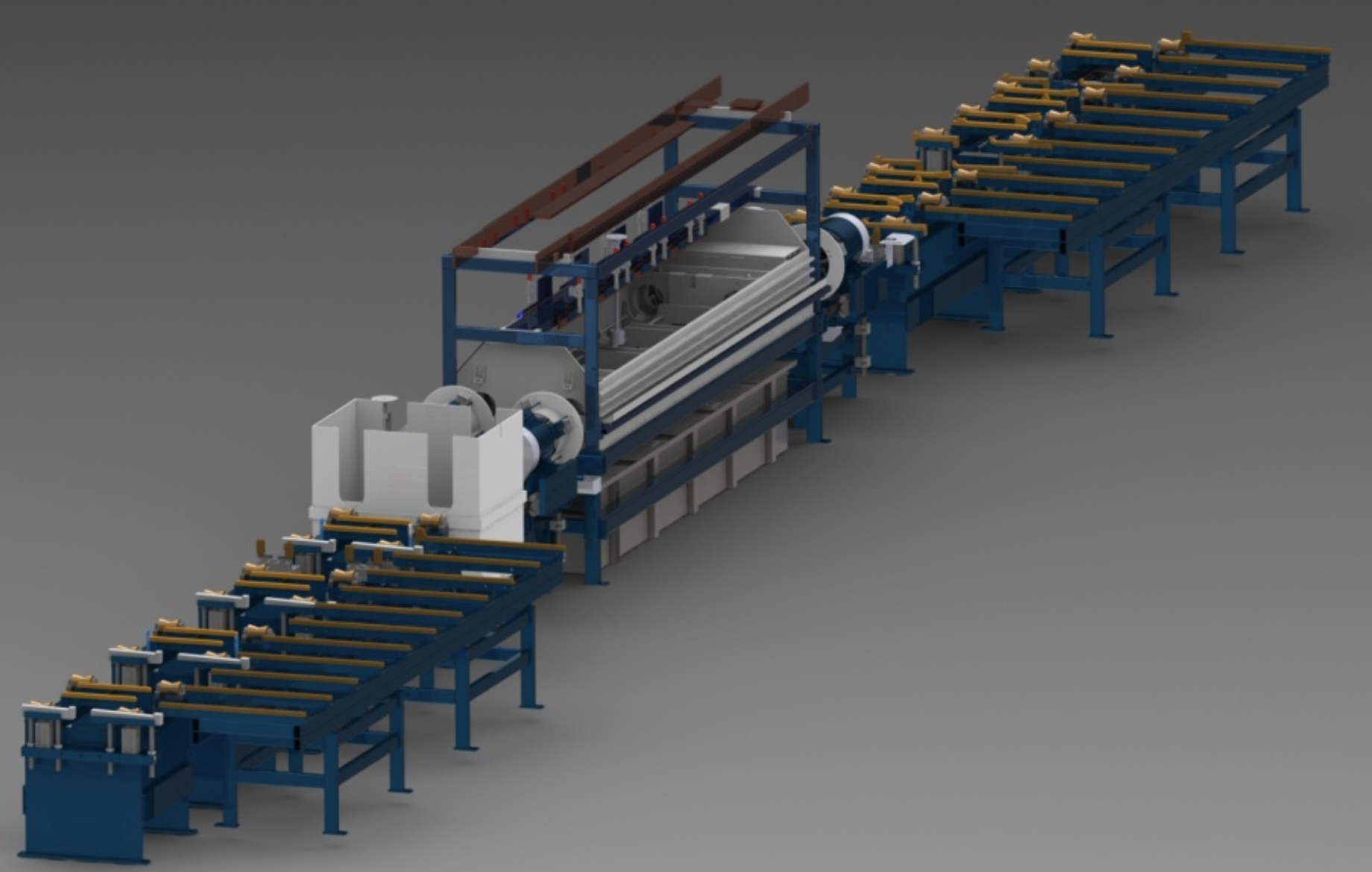

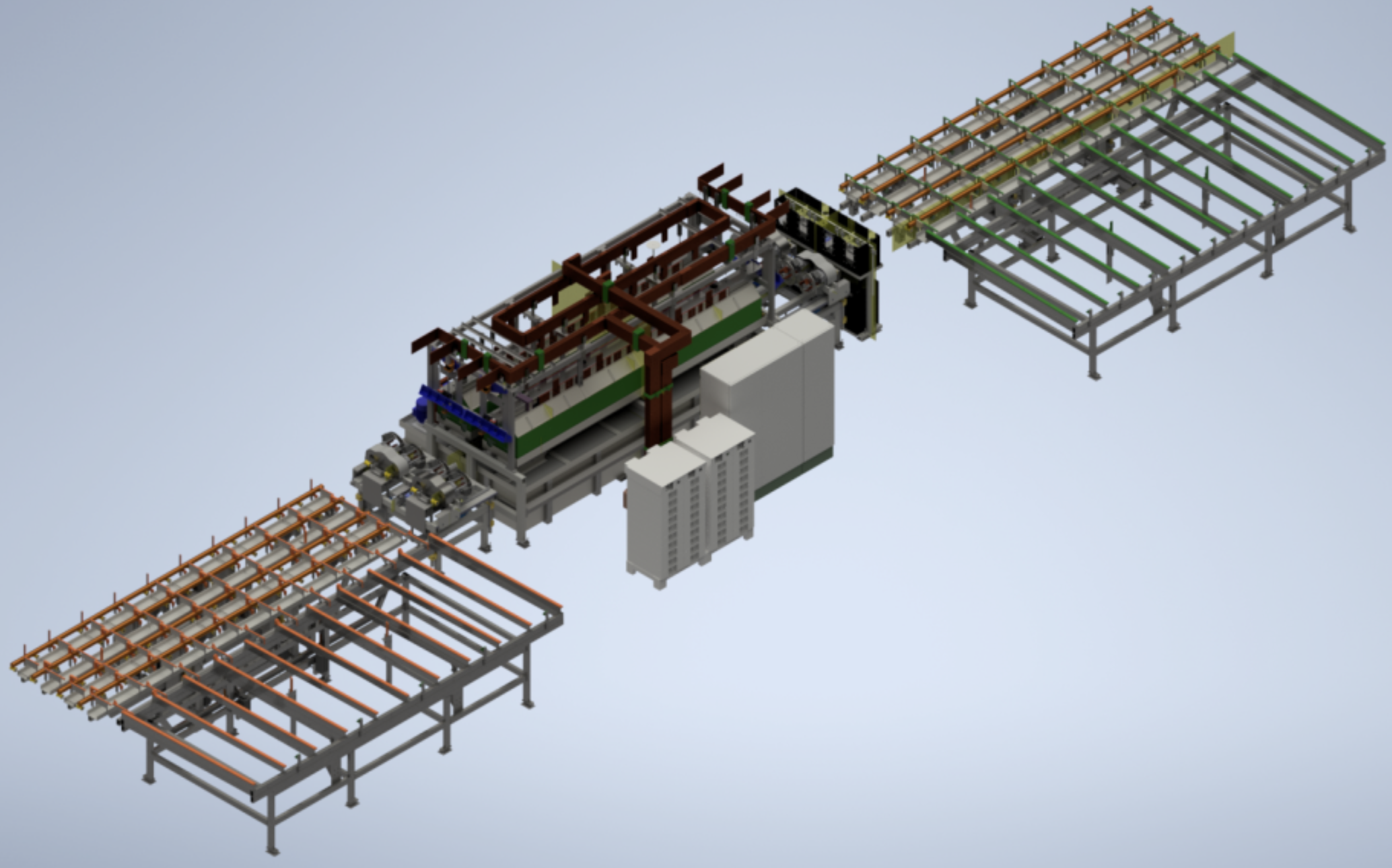

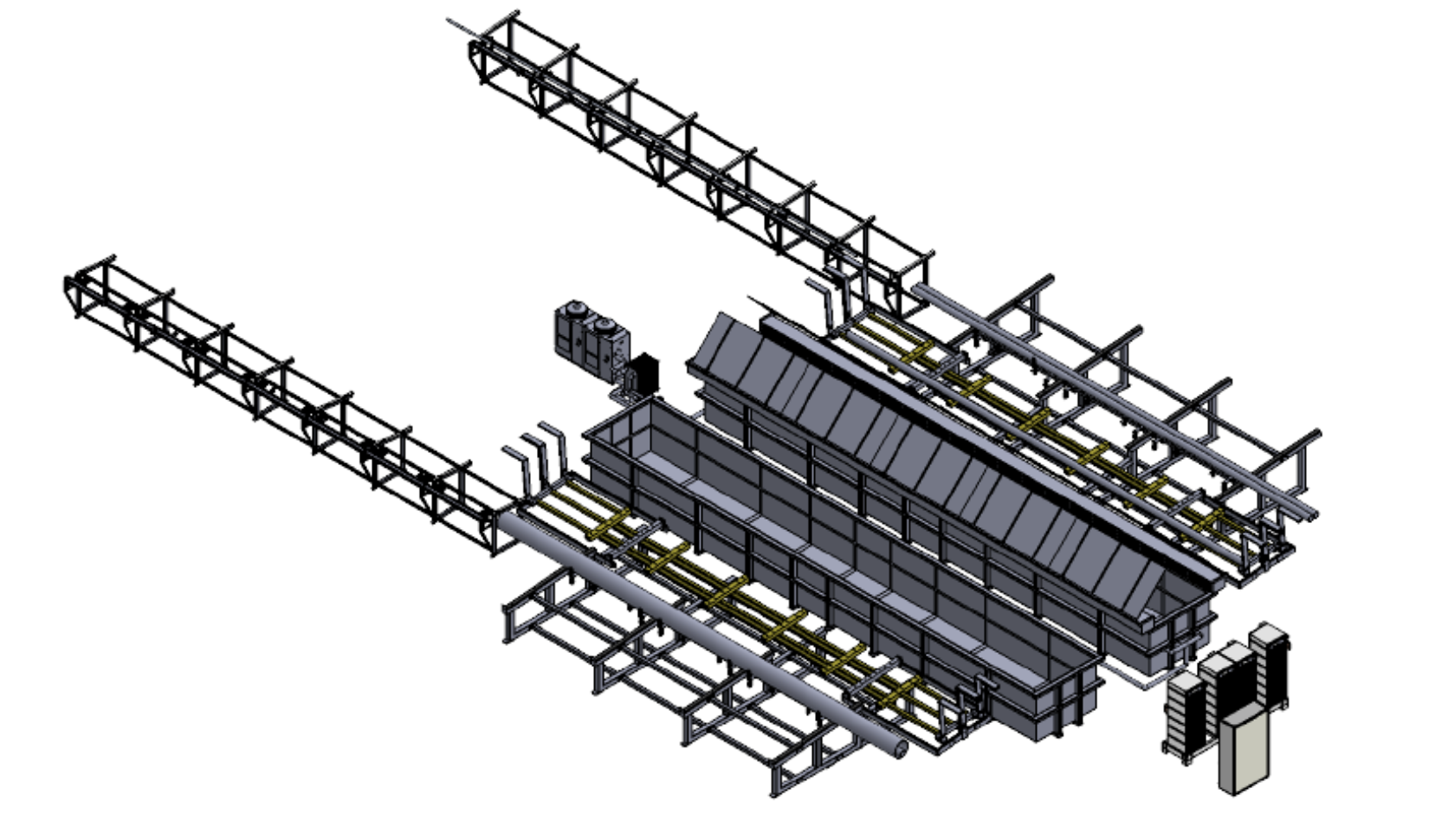

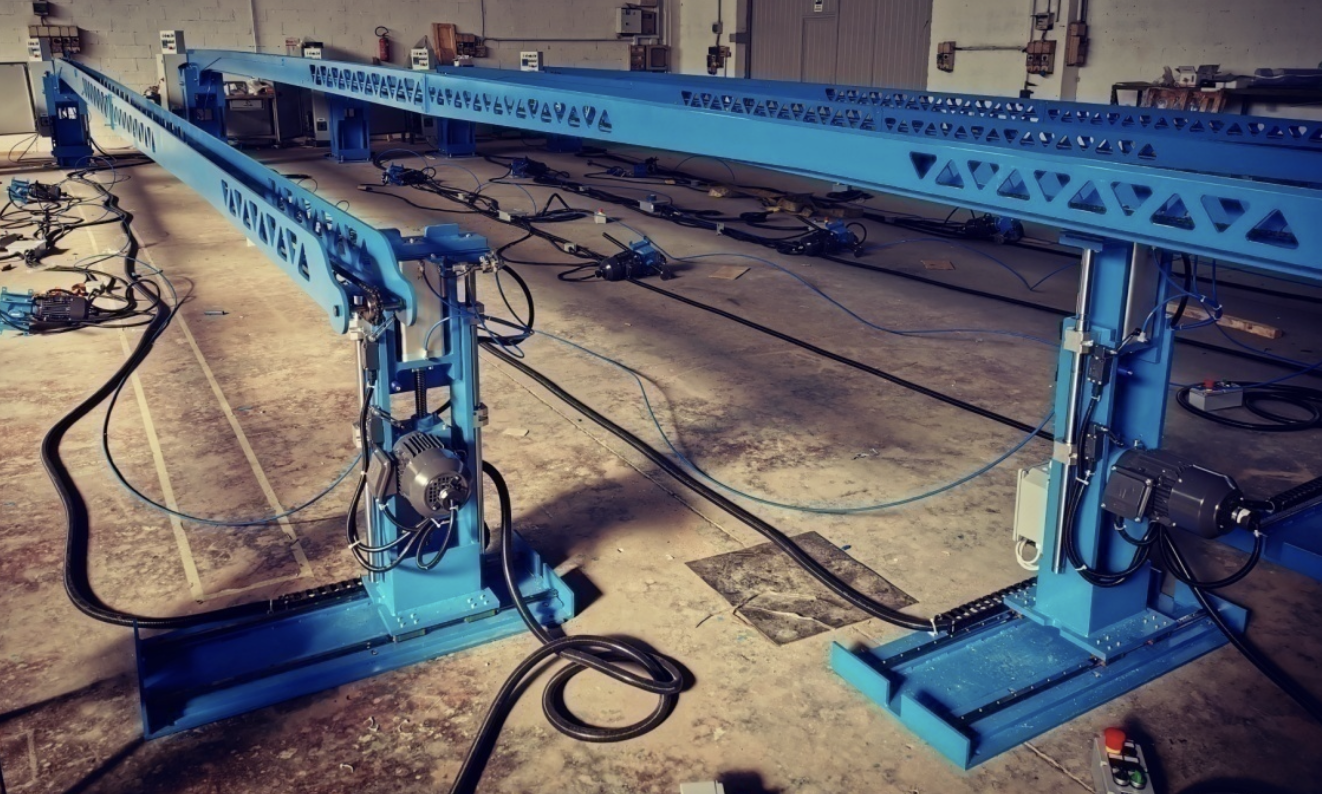

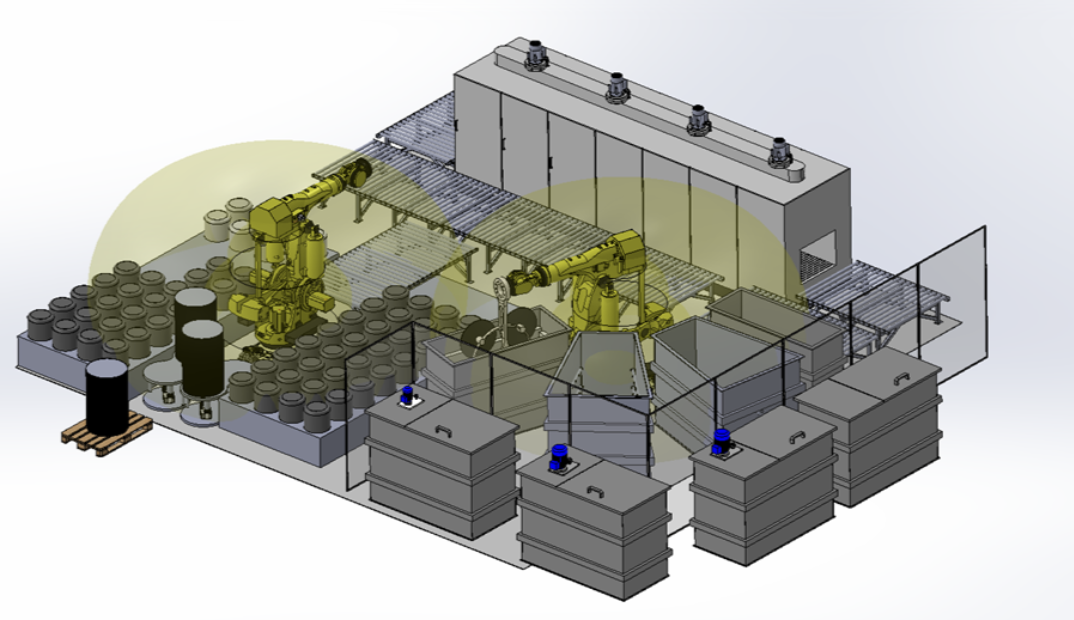

Automatic systems composed of loading paving, feeding clamps, galvanic area, extraction clamps and unloading paving. Final product quality, reduction of environmental impact, safety for operators are the main characteristics of an automatic chrome plating system. These are completely automatic systems and can be monitored by a single operator, who will simply have to set the process parameters and load and unload the bars from the layers. The software also helps the operator in choosing the parameters by automatically calculating the thickness of chrome deposited and the productivity of the system itself based on the parameters themselves. The system can be sized according to the products to be treated in 2 main typologies:

- Continuous bar chrome plating plant with 2 parallel lines (TALOS)

- Continuous bar chrome plating plant with 4 parallel lines (PHILON)